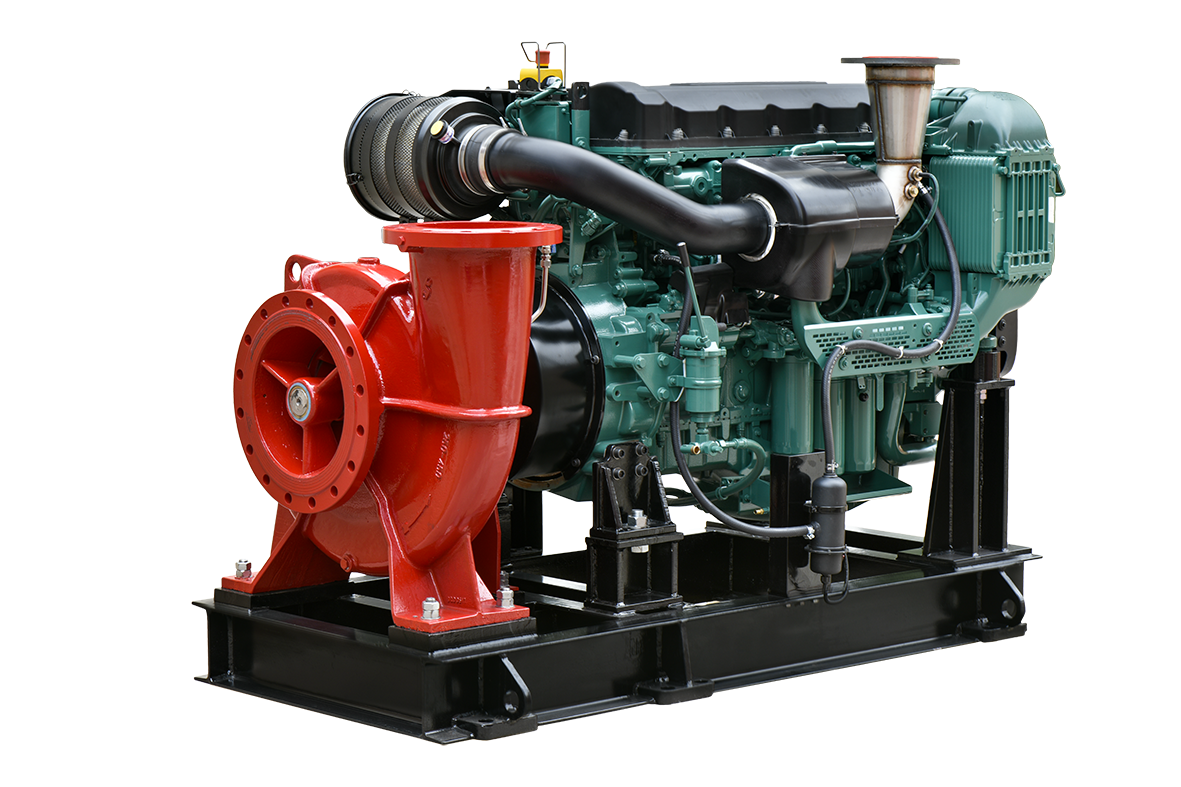

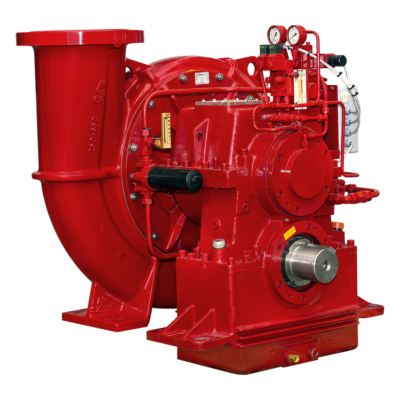

External Fire Fighting System pumps are provide a unique combination of high performance in relation with weight and dimensions. The pumps are designed as single stage volute casing horizontal centrifugal with close impeller and end suction/top discharge flange positioned. The horizontal double suction split case type centrifugal pumps are also available for higher capacities

We provide pump capacities according to IACS Classification rules for Fi-Fi 1, Fi-Fi 2, Fi-Fi 3 applications. The capacity ranges of the pumps are between 100 m³/h to 2800 m³/h

Pump casing material is Nodular Cast Iron (GGG40) as standard and inside of casing is coated by based on epoxy paint for sea & salt water resistance & corrosion. Bronze (CuSn10Ni) casing is also available depends on customer’s specification.

Marine Class Certification and approvals are available according to customer’s demand or request.

The EFF Pump can be driven by Dedicated Diesel Engine according vessel specification request.

The EFF Pump can be driven by E-motor according vessel specification request.

This type pumps are generally specified in the specification when the vessel having large electric production capability.

Frequency converter or Soft starter may be used for this type of systems.

The EFF Pump can be driven by Hydro-motor according vessel specification request.

This type pumps are generally specified in the specification when the vessel having large hydraulic power unit.

Generally small capacity EFF pumps are driven with hydro-motor.

Single Input/Single Output, Single Input/Double Output Step-up Gear Boxes are available and hydraulic operated built-in clutches are installed to Step-up Gear Box. Fire pumps can integrate on Step-up Gear Boxes in order to reduce dimensions of the units. Vertical or horizontal shaft offsets can select according to customer’s specifications.

Wide ranges of Step-up Gear Boxes are available for FI-FI 1, FI-FI 2 and FI-FI 3 applications. All step-up gear boxes are able to delivery with Marine Class Certifications/Approvals according to customer’s demand or request.

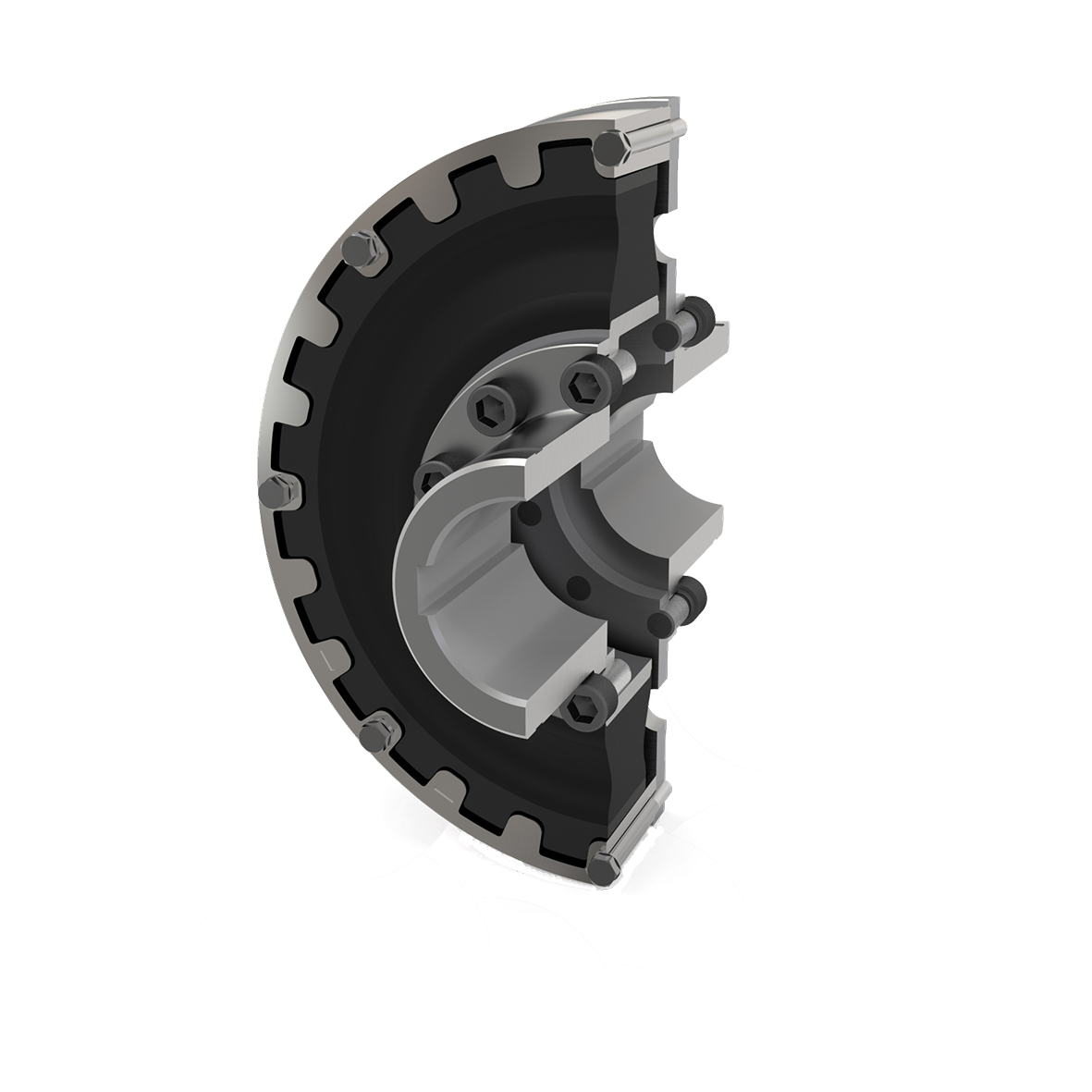

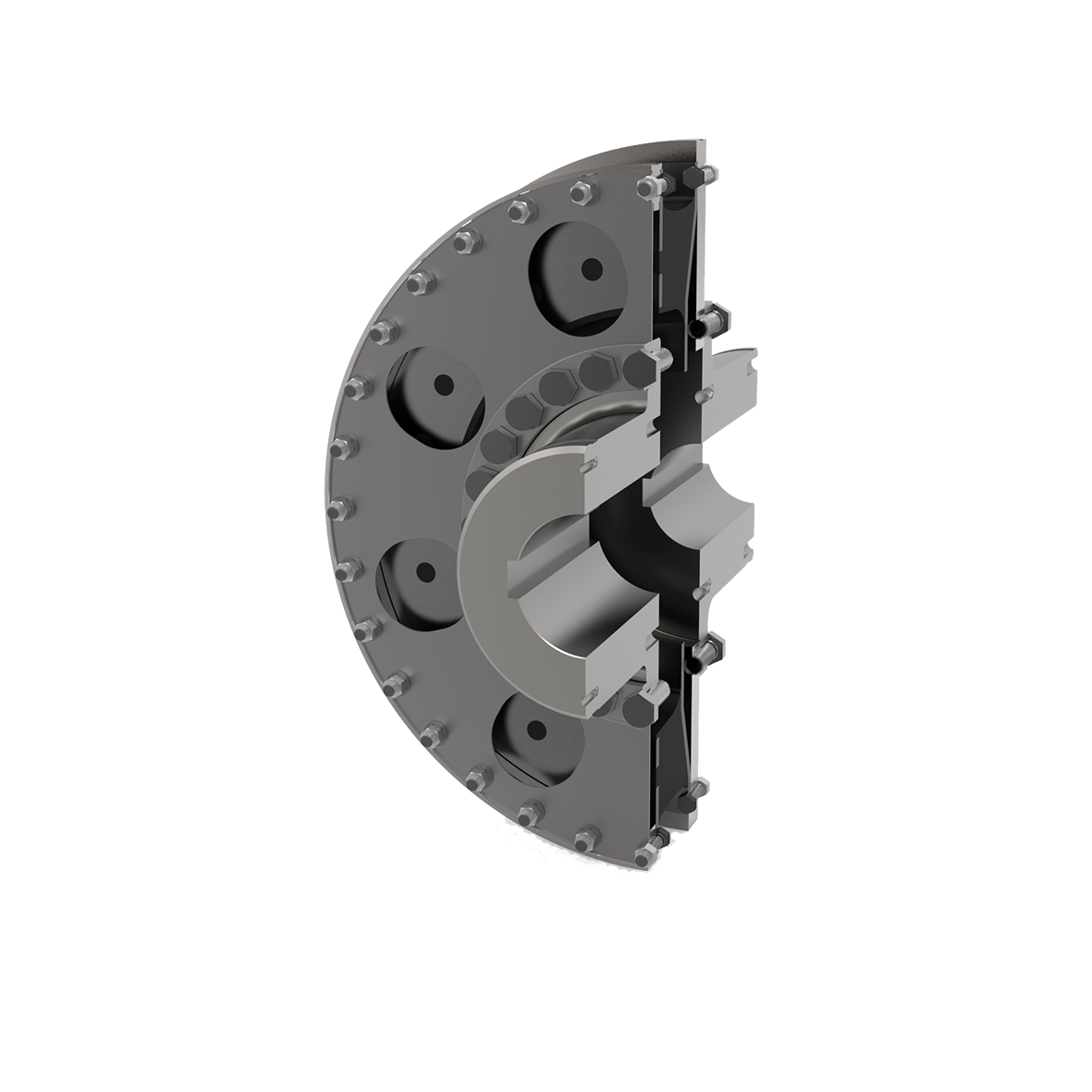

Hydraulic actuated clutch and flexible coupling combination can be used as a compact unit when main engine of the vessel and pump speed are same. The clutch unit will be fully integrated with pump and resulting very compact design.

PTO Couplings are a highly-flexible rubber coupling with linear characteristic, in particular suitable for Diesel-Engine drives. The series covers a nominal torque range between 1150 Nm and 20000 Nm; all kind of PTO connections can make according to specification.

Fire monitors designed for marine external fire-fighting systems and fixed mounting on pipe end. The monitors optimized to delivery of water with full flow and/or foam with reduced flow capacity to throw solid jet and fog which is spray pattern. The monitor rotations and the other operations are controlled by the individual electric motors as well as electric actuators for remote control. In addition to this the movements can be operated by manually. Electro hydraulic operated monitors are also available.

The capacity range of monitors are between 100 m³/h to 2400 m³/h.

All monitors have type approval certificate by the IACS classification society.

The EFF Control System is design based on PLC to control of all equipment’s (valves, clutches, monitors etc.) in a sequence by remotely. The system is designed and manufactured for marine external fire fighting systems.

Remote Control Panel is designed as flush mounted on wheel house control console and the system can control from the unit completely.

Portable remote control panel is an option. There is two possibility designed as cabled remote control delivered with 15 m cable or radio remote control depends on customer’s demand and request.

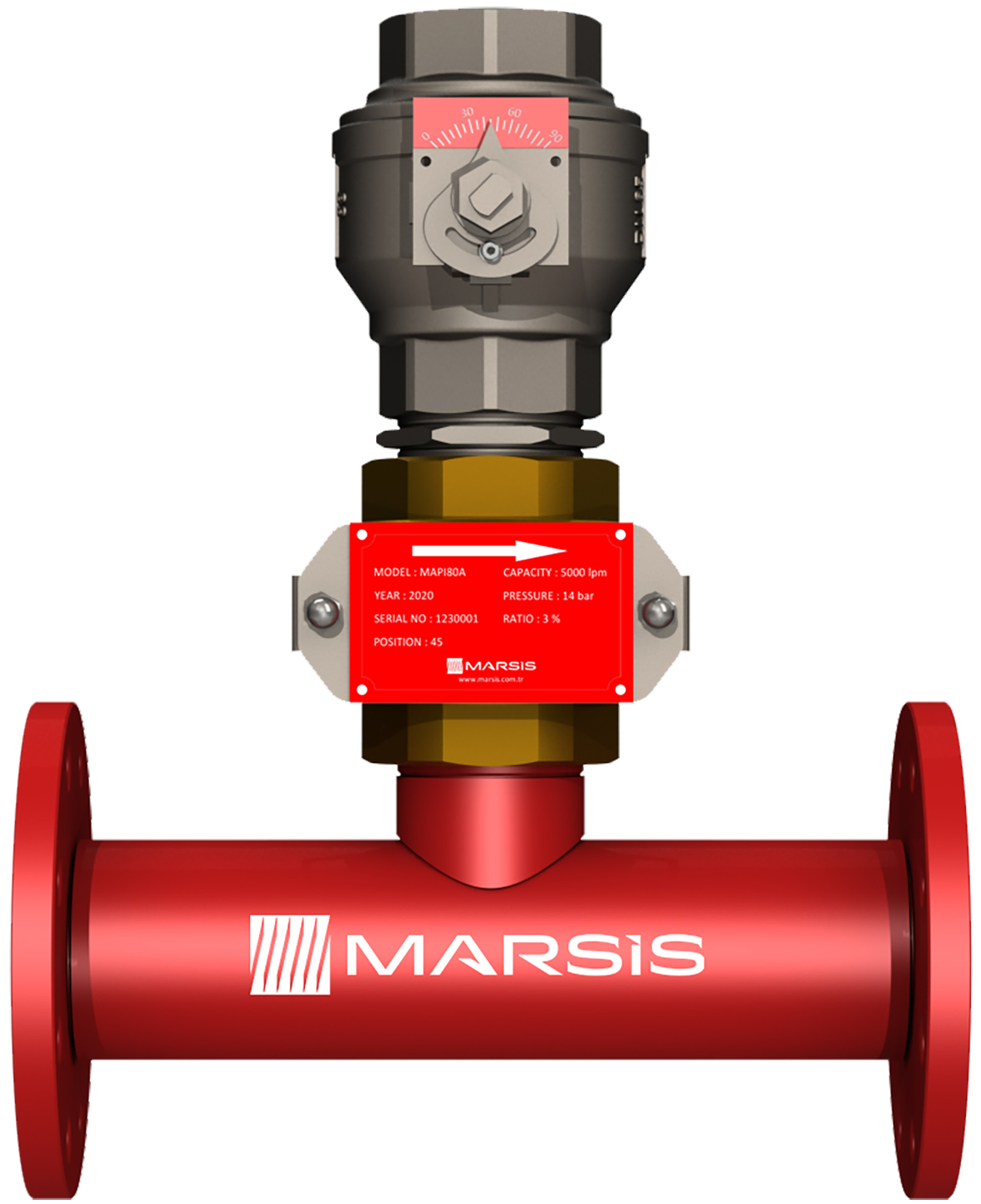

The Around Pump Inductor is used to mix a certain ratio of foam liquid into the main water line with vacuum effect and foam Inductor is designed and manufactured by MARSIS for a pre- determined water flow and pressure to provide the correct proportioning rate.

The Around Pump Inductor which called MAPI is connected in a bypass between the pressure and suction side of the fire pump. MAPI has an adjustable between 0-6% and foam concentrate suction capacity up to 420 lpm.

The Balanced Pressure Proportioner that called PP makes foam concentrate in to the water feed line and it has wide range foam concentrate suction capacity. The proportioning can adjusted at site.

The foam concentrate is supplied to proportioner by a pump. The type of pump is vertical, multi-stage in-line centrifugal pump and the material of it made by stainless steel which is resistance to foam liquid.

The water spray system is designed to protect the ship from the fire and heat emanating from the fire zone during the fire-fighting operation.

The system can designed based on 10 lpm or 5 lpm per square meter flow capacity of vertical areas according to general arrangement of the vessel. Complete flow calculation and design of the water spray systems are approved by Marine Classification Society.